TB Wood's L-Jaw® Couplings

Posted by Voigt-Abernathy Store Team on Jan 24th 2018

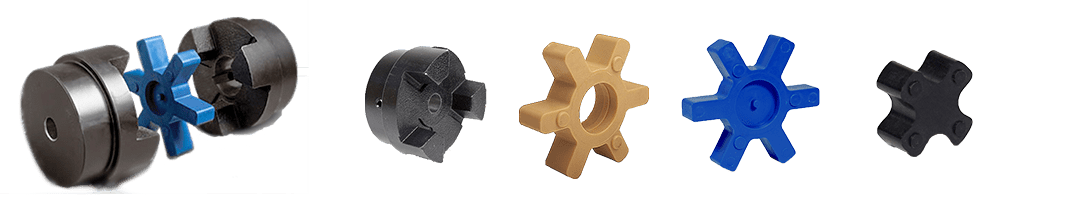

L-Jaw® elastomeric couplings were created to meet high quality

standards while being affordable to the consumer. L-Jaw® couplings are

part for part interchangeable with industry standard design, and

their hubs are available in a large range of bore sizes. L-Jaw® coupling's fail-safe design will

continue to drive even if the elastomer fails, and they require no maintenance

or lubrication to operate. A L-Jaw® coupling assembly consists of one spider

insert and two hubs. Spider inserts are available in three

materials-Buna-N, Urethane and Hytrel, and L-Jaw® hubs are available in Sinter

Carbon Steel and Cast Iron construction.

Some benefits of TB Wood's Jaw Couplings are:

- No Maintenance or lubrication needed

- Part-for-part interchangeable with industry standard design

- Fail safe design that will no effect equipment performance is elastomer fails

- Wide range of inch and metric bore sizes

So what is an elastomeric coupling?

Elastomeric couplings include an insert made from elastomeric polymer, a highly flexible and durable rubber, that can withstand large amounts of stress and pressure while transmitting torque. In jaw type couplings, the elastic insert, known as the spider, acts as a shock absorber while interlocked between two metal hubs. The spider is meant to wear down before any damage is contributed to the metal hubs, saving time and money on maintenance. Jaw type elastomeric couplings are considered to be fail safe because when the spider fails, the hubs will interlock and continue to transmit torque, preventing damage to the machine and giving engineers time to service the equipment.

Check them out on our store here:

US Dollars

US Dollars